Integrated mounting solution for solid state spin sensors used for bulk detection and imaging

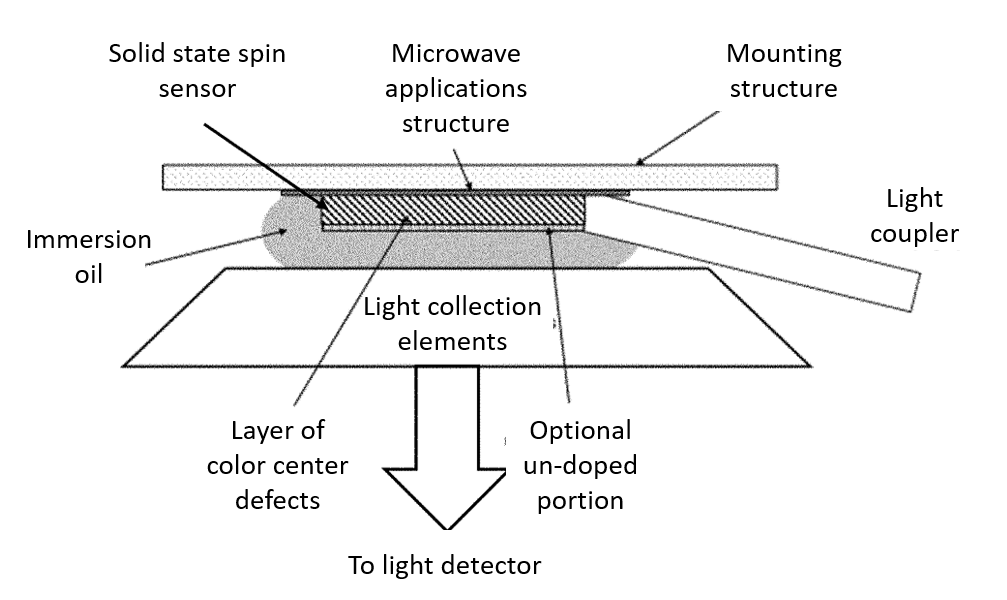

Sensors based on solid state spin system for measuring magnetic fields, electric fields, temperature, pressure, and other physical quantities can offer high resolution sensing at low cost and low power input. These systems employ point defects in crystal lattices, such as nitrogen-vacancy (NV) centers in diamonds, as quantum sensors. In typical use, an optical source is used to excite an array of sensors, and the value of the physical quantity is inferred from the measured amplitude modulation. However, the excitation can deposit heat into the system, which can contribute false signals. Excess heat may also prevent use of the system with temperature-sensitive samples, such as biological samples. Additionally, vibrational displacement of the sensors relative to the optical excitation source can affect measurement sensitivity. Thus, a stable mounting platform that can remove heat from the system is desirable to enable solid state spin sensors to operate at their full potential. Metals such as copper and aluminum are widely used as heatsinks due to their high thermal conductivity, however, the use of such materials for mounting solid state spin sensors can be problematic since electrically conductive materials can interfere with delivery of microwave radiation.

This invention describes an integrated solution for mounting a solid state spin sensor using semi-insulating silicon carbide, metalized layers for applying microwave radiation, and light couplers to efficiently deliver optical excitation. In addition to directing heat flow out of the system, the mounting structure facilitates delivery of optical excitation, does not interfere with microwave radiation, and provides a stable base to limit vibrations. This integrated mounting solution effectively enables quantum sensors for practical applications.

U.S. Patent(s) Issued: 10,928,320

Case Number: 6898